![]() The

Gaff Rig Page

The

Gaff Rig Page

"The Great Peak Halyard Controversy"

An examination of conflicting illustrations in

several "impeccable" sources!

Revised 01/31/01

|

"The Great Peak Halyard Controversy" An examination of conflicting illustrations in several "impeccable" sources! Revised 01/31/01 |

|

|

|

|

|

|

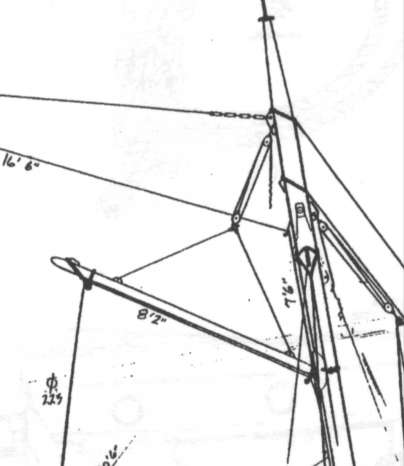

For an interesting "new" approach to gaff rig

halyards, see the Mainsail

page for designer Michael Kasten's cruising designs. He features

sailplans with a single halyard and a modified mainsail, but the pertinent

details are really more sail oriented. Here's a sneak peak at his

single halyard set up:

Keep in mind, this is on

a 50' schooner, not a day sailer!

Keep in mind, this is on

a 50' schooner, not a day sailer!

In May 2000, a designer emailed and indicated the peak halyard drawings below from "Knowing the Ropes" are "incorrect, and would not work." The falls and hoists of the peak halyards are where the problem lies, he says, as well as the angle that will be taken in the span when in full hoist. His promise of clarification hasn't been fulfilled, as I suspect he has gotten busy at work (boat building folks, like all self-employed people, have to take the work when it comes.)

Using one of the sources listed on The Gaff Rig Page, The Wooden Boat Forum, I asked if folks there could take a look and chime in. Several experienced Gaffers spoke up, took a look at the drawings, and offered the comments below.

Here is the original content on The Gaff Rig Page Detail Pages that

sparked the controversy:

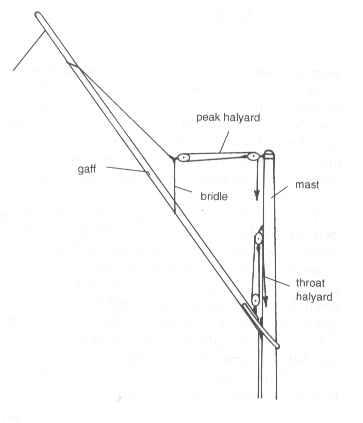

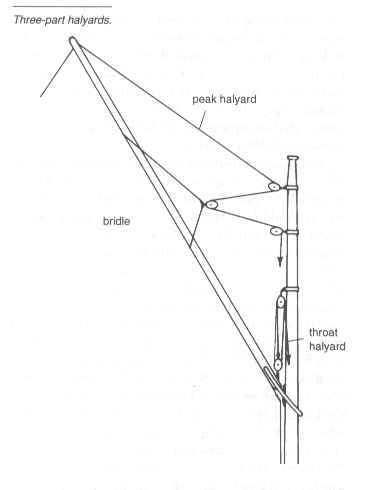

Three part halyards are

just a variation on the theme. For the throat halyard,a single becket

block is attached to the gaff near the jaws, and a double block is attached

to the mast. The throat halyard starts at the becket, is rove up

through one sheeve of the double block from aft to forward, back down through

the sheeve on the becket block from forward to aft, then back up around

the other sheeve on the double block from aft to forward and down the mast.

Easy enough. For the peak halyard, the bridle is attached just as

in a two part halyard. But you start the peak halyard sheet at the

end of the gaff, through a single block that is placed high on the mast,

to a single block with an eye or fairlead that rides the bridle, then to

a single block on the mast and down. Rove this sheet from top to

bottom on all blocks. This much purchase is needed when dealing with

gaff sails in excess of 100 square feet.

First to respond to my query on The Wooden Boat Forum was Ian McColgin, who indicated that there are many ways to rig the peak halyard, but to be aware that there are different stresses induced. The size of the sail, length of the gaff, angle of the gaff and height of the "truck above the normal location of the jaws" are all variables that might induce you to rig it one way or another. Most of the peak halyard rigging he has done is designed to put the most mechanical advantage along the middle two thirds of the gaff, which allows the gaff to bend a bit and the peak to sag off under strain. That avoids having the stress concentrated at the peak itself, putting a huge compression strain on the gaff and the mast at the jaws. Ian's comments regarding the many different ways to rig the peak halyard, and pointing out that different situations require different solutions seems to be the best explanation for the various rigs illustrated by the books.

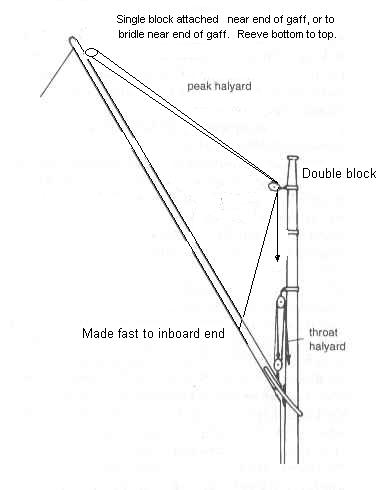

ACB (Andrew Craig-Bennet) posted that "its recokened to be bad practice" to have an end of a halyard ... the portion tied off to the becket on the left picture above ... since you can "freshen the nip" when both ends come down to the deck. The nip, I think, is where the halyard (line, rope) is compressed by the block when the sail is fully set. With the end of the halyard tied off aloft, the "nip" is always in the same place, and the halyard is subject to chafe and wear at that point. If you can adjust that point, your halyard will last much longer (which is why some with halyards tied off aloft have the habit of reversing the halyard every season.) But that aside, he also said, the drawings by Taylor show a disadvantageous lead since you are hauling on the part of the halyard that comes from the inboard end of the gaff; in other words, the stresses that Ian McColgin talked about are being concentrated on the block attached to the bridle which transfers those stresses to the inboard end of the gaff. It might be better, he suggests, to reeve the halyard "the other way around" by having the halyard made fast to the inboard end (nearer the mast) of the gaff, and the hauling part comes from the block outboard near the end on the gaff. I'm not positive about this description, not having a drawing to refer to, but it sounds like the halyard would start at a strap around the inboard end of the gaff, reeve up to perhaps a double block on the mast, out to a single block at or near the end of the gaff (either attached to the gaff or to a bridle spanning the outer end of the gaff) and then back to the double block on the mast and down. Here's a cobbled together drawing of what I think ACB is suggesting:

This does appear to put the effort towards the end of the gaff, as

the illustrations from Cunliffe's Hand Reef and Steer show (a bit below.)

ACB commented that my drawing was close, but he would choose two single

blocks at the top rather than a double block, to reduce friction.

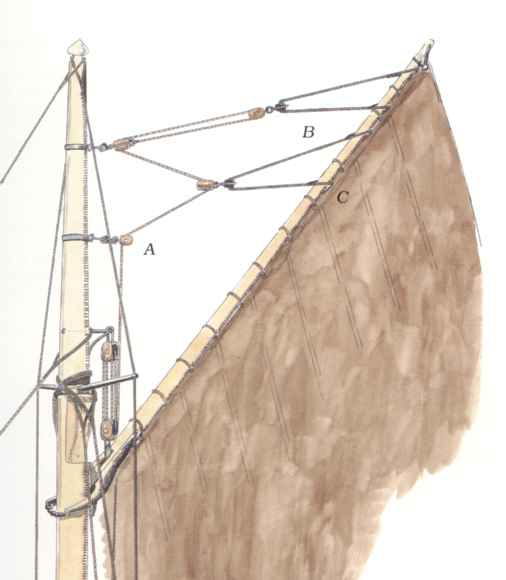

Don Braymer mentioned that he has a gaff with two yokes (or, bridles), steel cables spliced around the gaff that support a slider attached to a block. At the tip of the main mast, there is a bail that the peak halyard is made fast to, and another two bails that each shackle a block below that. The peak halyard goes from the shackle at the top of the mast to the aft (outboard) block on the gaff, back to the highest block on the mast (just below the bail where the halyard is made fast), back to the inboard block on the gaff, back to the lower block on the mast and to the deck. Tom Cunliffe's drawings, below, show this type of arrangement without the top bail on the mast; in Cunliffe's drawings, the halyard is made fast to a becket on the topmost mast block:

Note that this peak halyard

attaches to the gaff in the outermost quarter without a bridle spanning

in toward the mast. ACB later took another look at this drawing and

noted the problem with the "crane" seen at the "A" in the drawing above,

the extension from the mast, allowing the block at "A" to be positioned

away from the mast. He quotes Claud Worth, in 1911, who said the

crane was not a good plan, as it increases the twisting moment imparted

when the gaff is eased off while sailing. A better way is to attach

the block at "A" to a "long strop" that passes around the mast. ACB prefers

the end of the peak halyard, tied off to the becket in the uppermost block,

to be led down to the deck and made fast to a cleat, so you can "freshen

the nip." He also notes that there's more friction in this drawing,

as the hauling on the halyard is putting the most tension on the lower

bridle, toward the inbound end of the gaff, rather than toward the outbound

end.

Note that this peak halyard

attaches to the gaff in the outermost quarter without a bridle spanning

in toward the mast. ACB later took another look at this drawing and

noted the problem with the "crane" seen at the "A" in the drawing above,

the extension from the mast, allowing the block at "A" to be positioned

away from the mast. He quotes Claud Worth, in 1911, who said the

crane was not a good plan, as it increases the twisting moment imparted

when the gaff is eased off while sailing. A better way is to attach

the block at "A" to a "long strop" that passes around the mast. ACB prefers

the end of the peak halyard, tied off to the becket in the uppermost block,

to be led down to the deck and made fast to a cleat, so you can "freshen

the nip." He also notes that there's more friction in this drawing,

as the hauling on the halyard is putting the most tension on the lower

bridle, toward the inbound end of the gaff, rather than toward the outbound

end.

It should be noted that these illustrations, and many of these criticisms, are for problems you would run into with larger sails. After looking at my site, and seeing the Weekender in progress, Ian McColgin commented that she's a "wee bonny boat" and much of this conversation is more of an academic exercise. The stresses are not that great on a small gaffer with an 83 square foot sail. Looking at the plans for the Weekender (at the bottom of the page), he said "the rig drawn ought to work, but it does put a big strain on the gaff at that pully. I'd lash it, rather than bolt it in place, since the bolt hole will weaken the spar." A bridle with a short spread might even be better for my Weekender. An even simpler rig would be to have a bridle span from the outboard end of the gaff to where the block is, and had a sliding block on that bridle. On the mast, use a single block with a becket, make the halyard fast to the becket, then out to the block on the bridle, back to the block on the mast (reeving it from top to bottom) and down to the deck. He feels the stresses on the small sail are small enough that it would work fine that way.

Phil Young, who has experience from his dad's gaffer, notes that there

are no bridles and only two blocks on each halyard; an arrangement that

seems to work fine for the 23' boat he's familiar with. A strop attaches

the block to the gaff, about 2/3 towards the outboard end. The halyard

is tied off to the becket on the block on the mast, reeves through the

block on the gaff (top to bottom) then back to the block, and down to the

deck. His main point? "Keep it simple and it ain't that hard."

And I think that's probably the moral of the story for small boats.

These photos from Hand

Reef and Steer by Tom Cunliffe show both types of peak halyard attachment.

On the left is a Friendship Sloop with a peak halyard similar to Taylor's

design, complete with a bridle that spans the gaff's middle, and on the

right is a picture of a topsail (on another boat, of course) that shows

a peak halyard fitting the design above:

In the rest of the photos in Hand

Reef and Steer where you can see the peak halyard rigging, it appears

to follow either of these two designs. And it doesn't seem to matter

if the skipper has set a topsail flying or not.

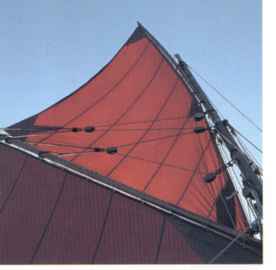

John Bertenshaw from Modulink in New Zealand sends along this picture of his peak halyard:

"I thought you might like the peak halyard shot. That purchase works fine and gets set up by hand and a little swigging. Mainsail is 610 sq ft. I put a winch on for it but don't use it much. I would of made the halyard double ended to shift the nip if I had known/conceived of it as your site suggests. Certainly use the photo. If you do please aknowledge AFA photography. Check out the album too if you like (click here for his photopoint album.)"Its not often that you have a Robinson R22 hovering over your head in 35 knots taking pics eh!!! It felt like he was right on us. Great day that it was.We did the same race a couple of weeks ago but got 5 through to 15 knots and topsail all the way! and won it!"

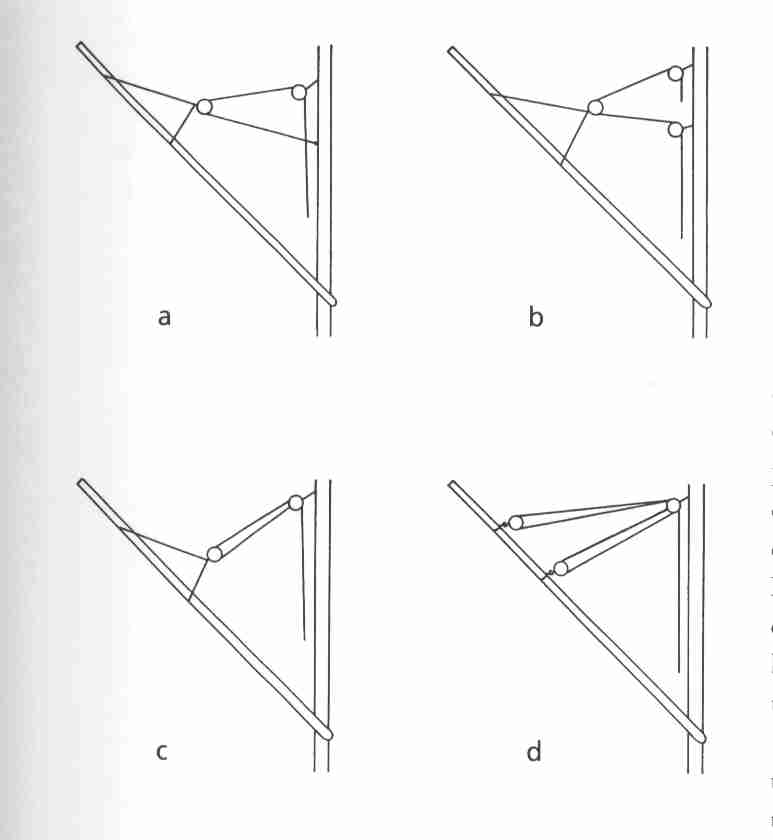

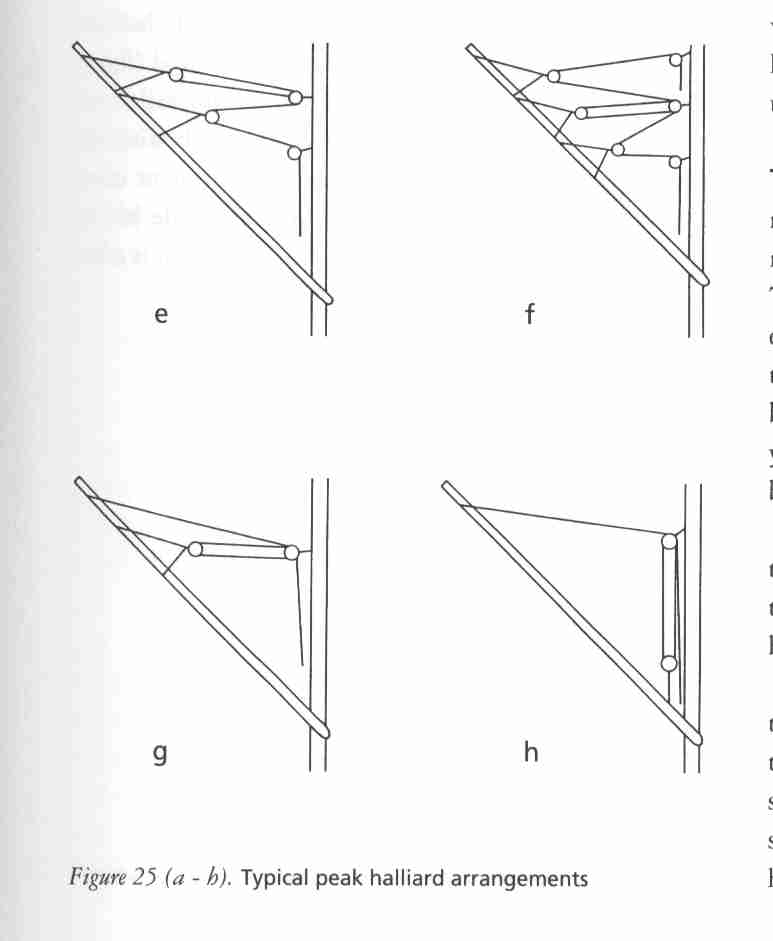

In the great "Gaff Rig Handbook" by John Leather, he treats the reader to eight, count 'em, eight different peak halyard treatments:

Note that figure "H" has a single halyard serving as both peak and throat halyard, which Leather says is used by some gaff rigs in sheltered waters.

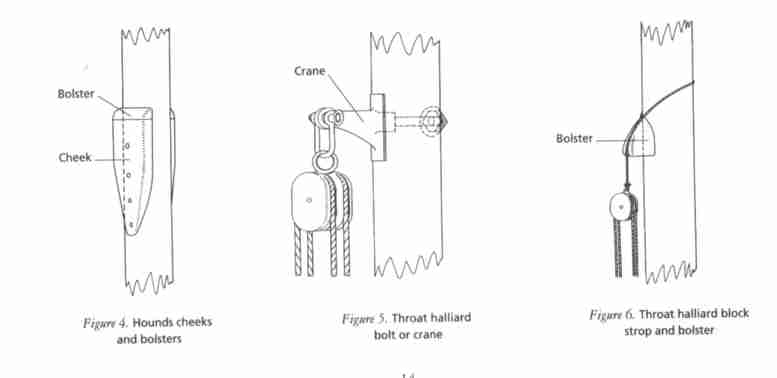

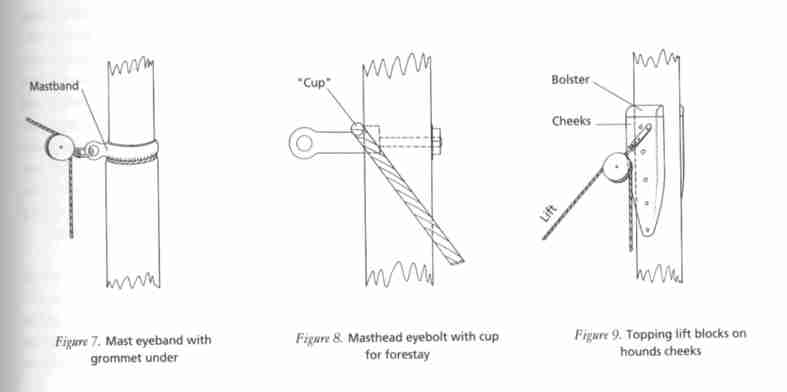

To crane, or not to crane was one question this controversy raised. ACB agrees with John Leather that a crane off the top of the mast to support the peak halyard topmost block is subject to great strain (again, on a larger sail -- most of this simply doesn't apply in the same manner to sails under 200 square feet, according to Leather.) Alternates to the crane shown in the color drawing above are presented here, from Leather's Gaff Rig Handbook:

The "strop and bolster" shown in Figure 6 is preferred by Brion

Toss also, even if combined with a crane. The stresses are carried

by the strop around the mast, and by the bolster to a greater surface area

below the strop. With the crane, the stresses are almost all concentrated

either on the area immediately surrounding the through bolt, or, if the

crane is bolted to the mast directly and not through bolted, to the top

bolt only. Other methods of protecting the mast from the pressures

invoked by running and standing rigging are also shown:

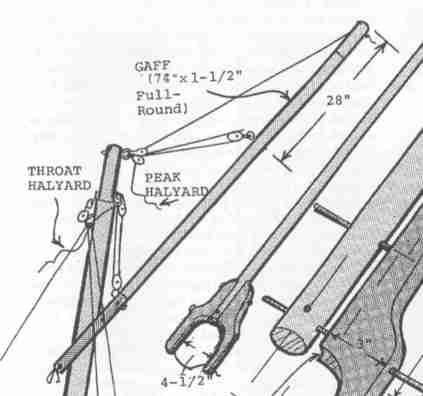

Ah, but for my "wee bonny boat," as Ian called it, here is the drawing from my own boat plans (the Weekender from Stevenson Projects) which shows the peak halyard attached at the end of the gaff, through a single block on the mast to a block located 28" from the end of the 74" gaff, then back to a block on the mast and then down. I'll probably take Ian McCoglin's suggestion to rig a simple bridle spanning the end of the gaff and set the block sliding on that, with the bridle spliced around the gaff rather than bolted through it.

Obviously, the Great Peak Halyard Controversy seems to mimic so many of the other controversies I've run into: heated debate and in the end, you find out much of the controversy is simply because there are so many choices, each with their own merits and problems.

|

|

|

|

|

|