The Building of Aslan

Updated 6/02/02

The Building of Aslan |

Updated 6/02/02 |

|

|

|

|

|

|

| The "in progress" pictures of how I converted the standard rudder box to house a tiller are still out at the developer's, so we'll have to wait for them. In short, I asked for pics of tiller set ups done by others, and cut out curved plywood to extend the existing rudder box up over the stern. Then I bought a Catalina 25 tiller, trimmed it down to fit between the top edges, and made a swing up tiller as you can see below. |

|

This is the tiller in the "down" position. Note the black flexible "kitchen cove molding" used to reduce turbulence between the stern block and rudder box. |

|

Here's a reverse-view shot of the tiller in the up position, where it will allow access to the stern hatch. |

|

Updated 8/12/01

After sailing Aslan for a while, I discovered the tiller was still too long. I decided to use some of the left over, old Douglas Fir stock I used for the mast and spars to make a shorter tiller as a test. Here, I'm tracing the outline of the Catalina tiller onto the Douglas Fir 2 x 4. |

|

The new tiller will be about 12" shorter. It will come just to the edge of the cockpit, instead of protruding into the cockpit as you can see in the top photo. After rough cutting the shape with the band saw, I then cut it to width on the table saw. Final roughing out on the band saw, and then work with the belt sander, ROS sander and sanding by hand finished up the shape enough for this test. |

|

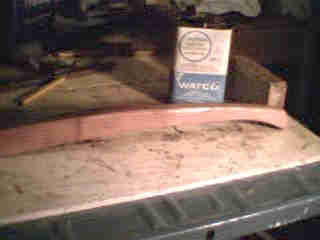

If this tiller works, I will either make a new laminated tiller or

shorten the Catalina tiller. So for the test, I'm simply putting

an oil finish on it. My dad had this can of Watco Marine Finish,

a danish-oil kind of finish that is no longer available. So I'm applying

several coats of it.

This coming weekend we'll test the new shorter tiller, and I'll include an update here. |

|

Updated 6/2/02

I sailed with the shorter tiller a couple of times during gentle breezes, declared it good, and whacked off the end of the $50 Catalina tiller. But, as is usual with me, I found during real wind it was a chore to hold onto. Not wanting to spend another $50 on a tiller, I ripped some 1 x 2s of douglas fir and mahogany, then resawed them. To resaw a piece of wood isn't to saw it again, but to rip it "the hard way", by cutting the narrow edge. After deducting for the saw kerf, I ended up with 1/4 x 2" wide strips of wood. I put several strips of PVC packing tape to protect my saw table, slathered the wood with epoxy, and then used clamps to bend the strips slightly (a 1" thick piece of wood is in the center, and the ends are bent around it.) |

|

After the epoxy had set, I marked out the shape of the new tiller and used the band saw to cut out a rough blank. For the aft portion of the tiller, where it fits between the sides on the rudder box, I used the band saw to cut "cheeks" off of the blank. |

|

Here, the blank is cut out and partially shaped. To shape the blank, I used a block plane, belt sander, random orbital sander, and curses. After satisfying myself with the shape of the tiller, I sanded to 200 grit and applied 5 coats of Helmsman Urethane Spar Varnish ... which I discovered when re-doing my bowsprit. The Helmsman Urethane Spar Varnish has worked great on my bowsprit, which pokes out under the cover and gets maximum UV. |

|

So here it is on Aslan ... again, a longer tiller. The disadvantage is that it takes up a bit of room. But I mostly sail alone or with one other person these days; the Weekender is too small to comfortably sail with more than two "full sized" adults in it. |

|

One other modification ... I added a reinforcing bolt under the tiller, to hold the sides of the rudder box together. I noticed some cracks starting where the stresses were delaminating the plywood sides. |

|

|

|

|

|

|